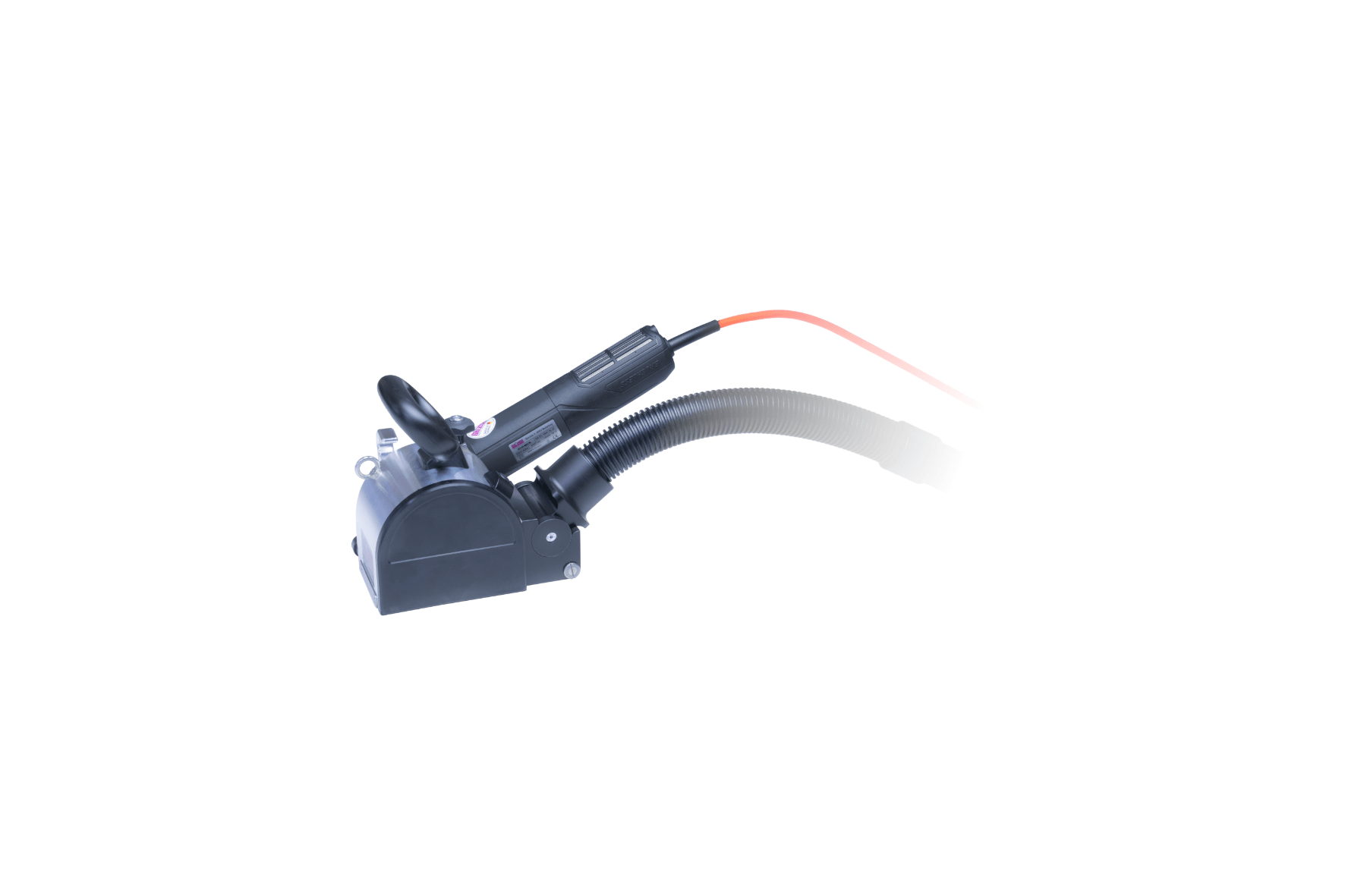

ATLAS MAX BL:

- Designed for low dust level. The rotation of the milling cylinder throws the removal exactly in the direction of the dust extraction. This leads to the best extraction results.

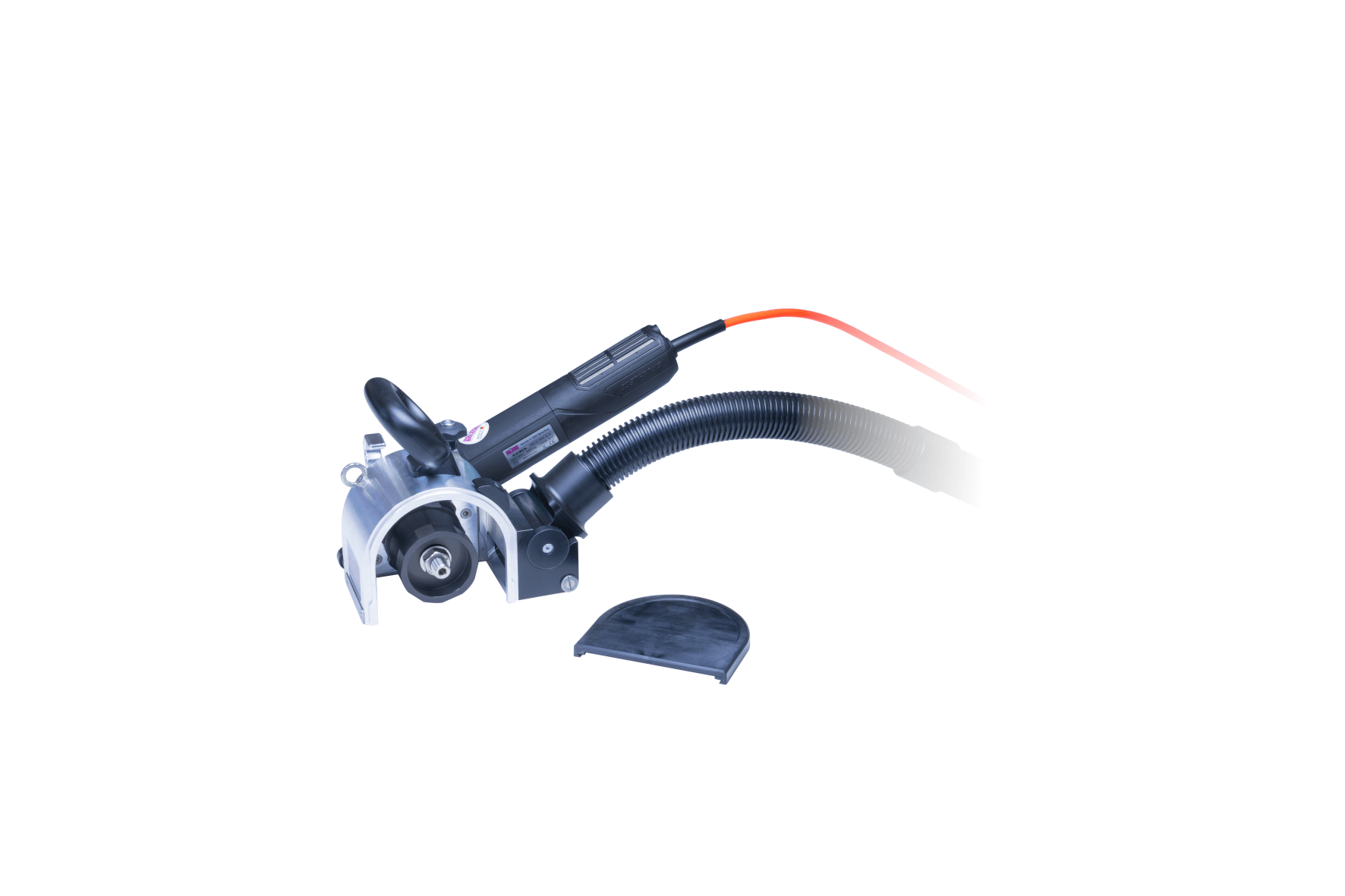

- In combination with the PCD milling drum (see reverse side) the surface is peeled off (no grinding).

- Accurately defined removal. Polycrystalline diamond-segmented tools in connection with an exact depth adjustment (0 – 10 mm) lead to an accurately defined layer of removal.

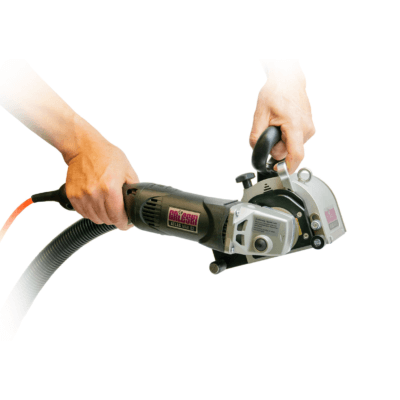

- Close-to-wall (close-to-floor) milling (border areas). The body of the machine can gradually be adjusted during the work process from „vertical“ to an upright position and even further.

- Magnetic motor without carbon brushes. The previously necessary, regular carbon replacement is completely eliminated. Therefore: fewer costs, less work, fewer sources of error.

- Significantly more torque. This is particularly noticeable in the lower speed range, e.g. when polishing.

- High efficiency (Up to +30%). The omitted frictional resistance of the brushes and other factors result in higher efficiency.

- Long service life. The service life of ordinary brand angle grinders is exceeded by several times.

![GALESKI [EN]](https://galeski.net/en/wp-content/uploads/sites/2/2024/02/Logo_Normal-transp.png)